INDUSTRIES

Subsea & Land Based Downhole Systems

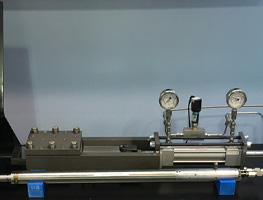

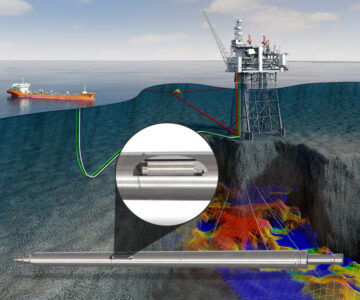

CDA motors are prime movers for electrical or hydraulic actuation systems across the breadth of oilfield services where high reliability, extended life is critical product features. Semi-custom downhole rated motors, actuators and rotary sensors developed to work in conjunction with controllers and other electronic feedback devices to achieve a highly reliable and power dense solutions for the oil and gas market.

Our heritage includes use on subsea and land based systems downhole systems where communication of information and well integrity is of the upmost importance.

CDA in Downhole Service Tools

- Developed actuation solutions in the early 1980’s for some of the premier drilling and well intervention tools of the time. Some of which are still in use to this day.

- CDA has been part of the tool development market in the US, Norway, Canada, UK, Asia where these tools have provided service around the globe.

- We have been part of approximately 150 different tool applications for various design companies in the servicing market.

- High temperature, high pressure, compact diameter, high power density and reliability are some of the primary attributes that make us an actuation leader in this market.

Our Downhole Partners

KEY AREAS OF FOCUS

High

Temperature

High

Pressure

Push the Bit &

Point the Bit

Pulser

Actuation

Subsea / Completion Applications

Wireline / Well Intervention Applications

Want to know more about our Downhole products?

Call us at (954) 698-6000 or fill out the form to have a member of our sales team reach out about your project.

When it has to work

We support missions where components must work every time, because if they don’t, the mission may fail and lives may be lost. That’s critical engineering at work. That’s fifty years of space, downhole oil & gas, and defense heritage. That’s CDA InterCorp.